Embark on a transformative journey with the Business Inventory Barcode System, an innovative solution that unlocks the gateway to enhanced accuracy, efficiency, and cost-effectiveness in inventory management. Dive into the realm of barcodes, scanners, and software, and discover how this system streamlines operations, empowers decision-making, and propels businesses towards success.

From retail giants to manufacturing powerhouses, the Business Inventory Barcode System has proven its mettle in a myriad of industries. Witness how this technology empowers businesses to optimize inventory levels, reduce shrinkage, and gain real-time visibility into their stock. Prepare to be captivated as we delve into the intricacies of this game-changing system, exploring its components, benefits, applications, and best practices.

System Overview

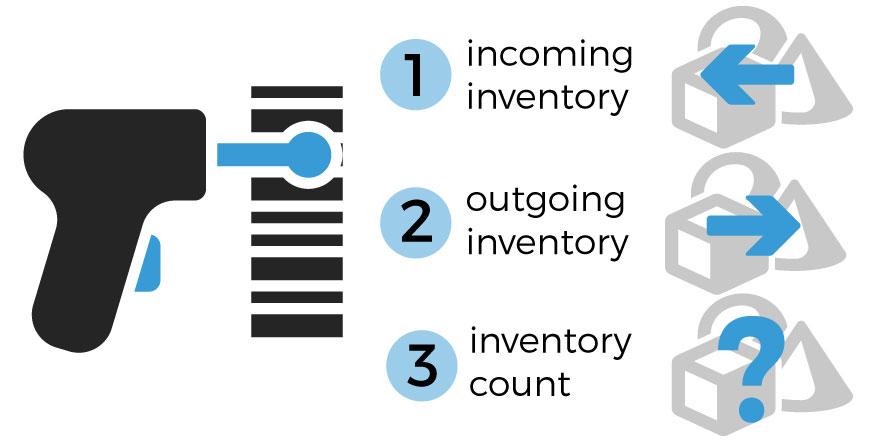

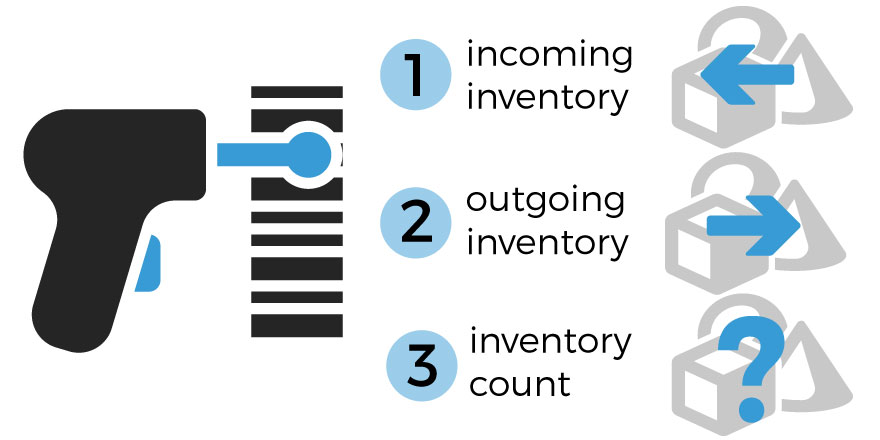

A business inventory barcode system is a technological solution designed to streamline the management of inventory within a business. It employs the use of barcodes, which are machine-readable optical labels that contain data about a product, to track and monitor inventory levels in real-time.

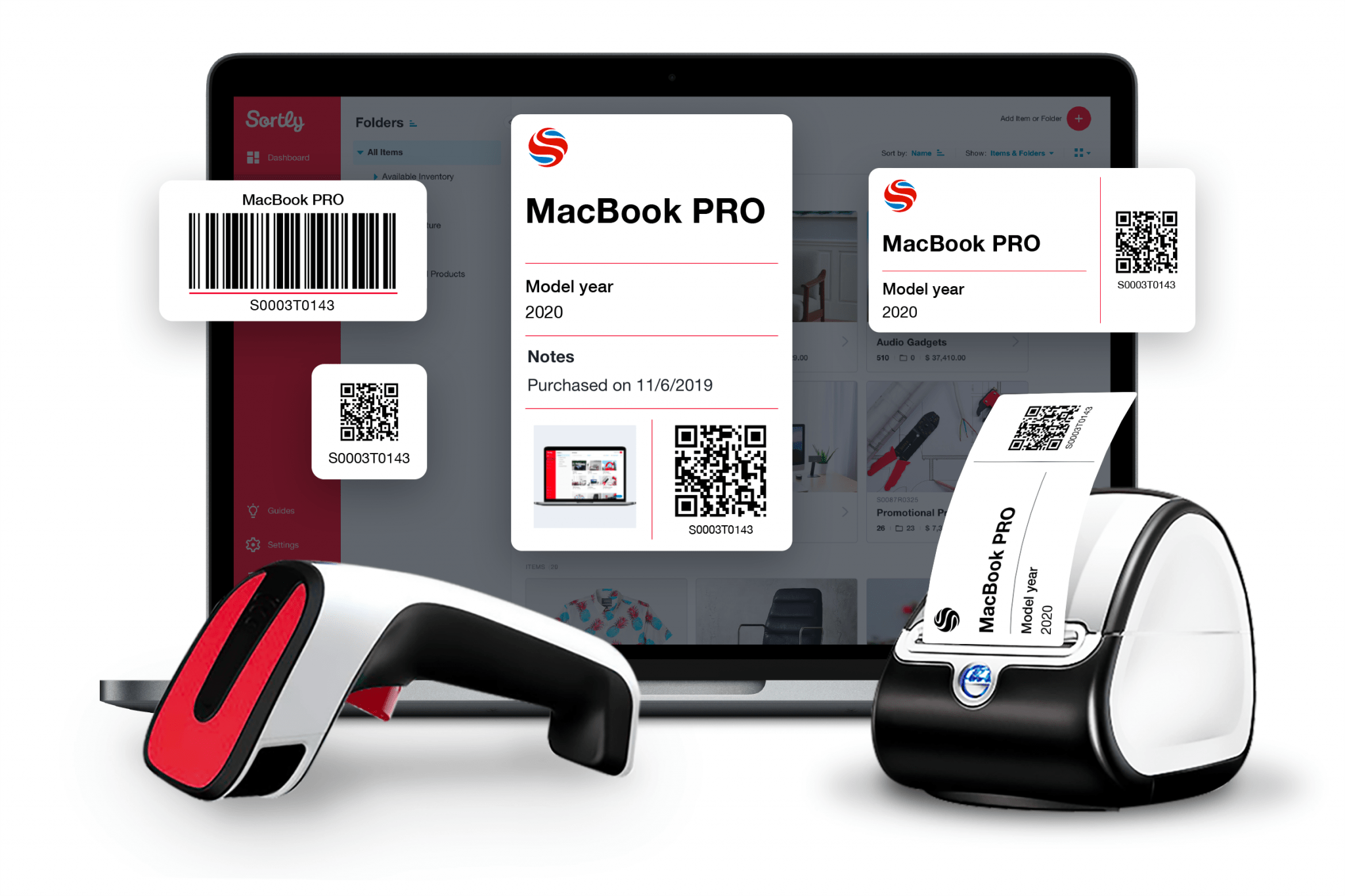

A typical barcode system consists of several key components, including barcode scanners, software, and barcode labels. Barcode scanners are used to capture the data encoded in the barcodes, while the software serves as a central hub for managing and processing the scanned data.

Barcode labels are attached to each item in the inventory, providing a unique identifier for each product.

Benefits of Implementation

Implementing a barcode system for inventory management offers a range of advantages, leading to improved accuracy, efficiency, and cost-effectiveness.

Barcodes provide a unique and standardized method of identifying and tracking inventory items, reducing the risk of errors associated with manual data entry and ensuring accurate inventory records.

Enhanced Accuracy

- Eliminates manual data entry errors, reducing discrepancies and ensuring reliable inventory data.

- Provides real-time visibility into inventory levels, enabling businesses to make informed decisions and prevent stockouts.

Increased Efficiency

- Automates inventory processes, saving time and labor costs.

- Streamlines receiving, shipping, and cycle counting tasks, improving operational efficiency.

Cost-Effectiveness

- Reduces labor costs associated with manual inventory management.

- Minimizes inventory losses due to improved accuracy and real-time tracking.

Barcode Types and Applications

Barcodes are a crucial component of inventory management systems, facilitating efficient and accurate tracking of items. Various types of barcodes exist, each with unique characteristics and applications.

Linear Barcodes

Linear barcodes, also known as 1D barcodes, consist of parallel lines of varying widths. They are commonly used for simple inventory applications due to their ease of scanning and cost-effectiveness.

- UPC (Universal Product Code): Used for retail products, it contains information about the manufacturer, product, and country of origin.

- EAN (European Article Number): Similar to UPC, used in Europe and other regions.

- Code 39: A more versatile barcode that can encode both numbers and letters, making it suitable for industrial applications.

2D Barcodes, Business inventory barcode system

D barcodes are more complex than linear barcodes, containing data in both the horizontal and vertical directions. They offer increased data storage capacity and can be scanned from various angles.

- QR Code (Quick Response Code): Widely used in marketing and logistics, QR codes can store a significant amount of data and be easily scanned by smartphones.

- Data Matrix: A high-density 2D barcode used in industrial settings and for tracking small items.

- PDF417: A 2D barcode designed for large data capacity, commonly used in transportation and healthcare.

RFID Tags

RFID (Radio Frequency Identification) tags are electronic tags that use radio waves to transmit data. They offer advantages such as non-line-of-sight scanning and the ability to track items in real-time. RFID tags are often used in asset tracking, supply chain management, and inventory control.

System Design and Implementation: Business Inventory Barcode System

Designing and implementing a barcode inventory system involves careful planning and execution. The following steps provide an overview of the process:

1. System Requirements Gathering: Determine the specific needs of the business, including the types of inventory items, data required, and desired functionality.

2. System Design: Create a detailed plan for the system, including hardware, software, barcode types, and data flow. Consider factors such as scalability, security, and user-friendliness.

3. System Integration: Connect the barcode inventory system with other business systems, such as ERP or POS, to ensure seamless data exchange.

4. Training: Provide comprehensive training to employees on the use of the system, including barcode scanning techniques and data entry procedures.

Factors to Consider

When designing and implementing a barcode inventory system, consider the following factors:

- System Scalability: Ensure the system can handle the current and future volume of inventory items.

- Data Security: Implement measures to protect sensitive inventory data from unauthorized access.

- User-Friendliness: Design the system to be easy to use and navigate for employees.

- Cost: Determine the upfront and ongoing costs associated with the system, including hardware, software, and maintenance.

Data Management and Analysis

Barcode systems revolutionize inventory data management by capturing real-time information about each item, providing a comprehensive view of inventory levels, locations, and movements. This data is stored in a centralized database, enabling efficient data analysis and retrieval.Barcode systems employ various methods to analyze inventory data for optimization and decision-making.

One method involves using inventory management software to generate reports that provide insights into inventory performance, such as stock levels, turnover rates, and lead times. These reports help identify slow-moving items, optimize stock levels, and forecast future demand.Another method is data visualization, which transforms inventory data into graphical representations like charts and dashboards.

This visual representation simplifies data interpretation, enabling stakeholders to quickly identify trends, patterns, and areas for improvement. Data visualization also facilitates communication of inventory insights to non-technical personnel.

Data Analytics for Inventory Optimization

Inventory analytics plays a crucial role in optimizing inventory management processes. By analyzing historical data and real-time inventory information, businesses can identify opportunities for improvement and make informed decisions. For example, data analytics can help determine optimal safety stock levels to minimize the risk of stockouts while reducing excess inventory and storage costs.Data analytics also supports demand forecasting, which is critical for aligning inventory levels with customer demand.

By analyzing historical sales data, seasonality patterns, and market trends, businesses can predict future demand and adjust inventory levels accordingly. Accurate demand forecasting reduces the risk of overstocking or understocking, leading to improved customer service and reduced inventory costs.

Integration with Other Systems

Integrating barcode inventory systems with other business systems is essential to maximize efficiency and accuracy.

By connecting inventory data with systems such as accounting, order management, and customer relationship management (CRM), businesses can streamline processes, reduce errors, and gain a comprehensive view of their operations.

Enhanced Efficiency

- Automated data transfer eliminates manual entry, reducing the risk of errors and saving time.

- Real-time inventory updates enable quick and informed decision-making, optimizing stock levels and preventing shortages.

- Integration with order management systems facilitates seamless order fulfillment, improving customer satisfaction.

Improved Accuracy

- Barcodes eliminate human error associated with manual counting and data entry, ensuring accurate inventory records.

- Integration with accounting systems provides a clear audit trail, enhancing financial transparency and reducing the risk of fraud.

- By eliminating data duplication across systems, inconsistencies and errors are minimized.

Best Practices and Case Studies

Implementing and managing barcode inventory systems effectively requires adherence to best practices. These guidelines help ensure accuracy, efficiency, and seamless integration.

Successful implementations in various industries showcase the benefits and ROI of barcode inventory systems. Case studies provide valuable insights into real-world applications and outcomes.

Best Practices

- Establish clear objectives and scope:Define the specific goals and boundaries of the system.

- Select the appropriate barcode technology:Consider factors such as industry standards, data capacity, and scanning environment.

- Standardize barcode labeling:Ensure consistency in barcode formats and data encoding.

- Implement data validation:Verify the accuracy of barcode data at the point of entry.

- Train staff:Provide comprehensive training on barcode scanning, data entry, and system maintenance.

Case Studies

Case Study 1: Retail Industry

A large retail chain implemented a barcode inventory system to streamline operations and reduce shrinkage. The system improved inventory accuracy by 95%, resulting in significant cost savings and increased customer satisfaction.

Case Study 2: Manufacturing Industry

A manufacturing company used a barcode inventory system to track work-in-progress inventory. The system enabled real-time visibility into inventory levels, reducing production delays and improving overall efficiency.

End of Discussion

As we conclude our exploration of the Business Inventory Barcode System, let us marvel at its transformative impact on inventory management. This system has emerged as a cornerstone of modern business operations, empowering organizations to achieve unprecedented levels of efficiency, accuracy, and cost-effectiveness.

By embracing this technology, businesses can unlock a world of possibilities, optimize their inventory strategies, and gain a competitive edge in today’s dynamic market landscape.

User Queries

What are the key components of a Business Inventory Barcode System?

A typical barcode system comprises scanners, software, and labels. Scanners read the barcodes, software interprets the data, and labels display the barcodes on inventory items.

How does a Business Inventory Barcode System improve accuracy?

Barcodes eliminate human error in data entry, ensuring accurate and reliable inventory records.

What are the different types of barcodes used in inventory management?

Common barcode types include UPC, EAN, and QR codes, each with specific applications and benefits.

How can I integrate a Business Inventory Barcode System with my existing systems?

Integration involves connecting the barcode system to other business systems, such as ERP or CRM, to ensure seamless data flow and enhanced efficiency.