In the realm of business, April holds immense significance for inventory management. From retail to manufacturing, industries across the board prioritize their inventory strategies during this crucial month. Understanding the intricacies of April business inventories is paramount for optimizing operations, maximizing efficiency, and driving financial success.

This comprehensive guide delves into the essential aspects of inventory management in April, exploring common strategies, forecasting techniques, and optimization methods. By gaining insights into industry-specific considerations, trends, and innovations, businesses can effectively navigate the challenges and opportunities associated with inventory management during this pivotal month.

Business Inventories in April

April is a significant month for business inventories due to the preparation for the upcoming summer season. Many industries rely on April inventories to ensure they have adequate stock to meet increased demand during the warmer months.

Retail Industry

Retail businesses typically increase their inventories in April to prepare for the summer shopping season. This includes stocking up on seasonal items such as swimwear, outdoor furniture, and grilling supplies.

Tourism Industry

Hotels, restaurants, and other tourism-related businesses also build up their inventories in April to cater to the influx of tourists during the summer months. This may involve purchasing additional food, beverages, and supplies to meet the increased demand.

Inventory Management Strategies

Businesses in April employ various inventory management strategies to optimize their operations and meet customer demand effectively. These strategies range from traditional methods to advanced techniques that leverage technology and data analysis.

The choice of inventory management strategy depends on factors such as industry, business size, product characteristics, and customer expectations. Each strategy has its own benefits and drawbacks, and businesses must carefully consider these factors to determine the best approach for their specific needs.

Just-in-Time (JIT) Inventory

- JIT aims to minimize inventory levels by receiving and using inventory items only when needed for production or sale.

- Benefits: Reduces storage costs, minimizes waste, and improves inventory turnover.

- Drawbacks: Requires accurate demand forecasting, can lead to stockouts if demand is underestimated, and may not be suitable for businesses with long lead times.

Economic Order Quantity (EOQ)

- EOQ determines the optimal quantity of inventory to order at a time to minimize total inventory costs, including ordering and holding costs.

- Benefits: Reduces total inventory costs, improves inventory turnover, and ensures optimal inventory levels.

- Drawbacks: Requires accurate demand and cost data, can be complex to calculate, and may not be suitable for items with fluctuating demand.

First-In, First-Out (FIFO)

- FIFO assumes that the oldest inventory items are sold or used first.

- Benefits: Matches the cost of goods sold to current market prices, reduces the risk of obsolete inventory, and simplifies inventory valuation.

- Drawbacks: May not reflect the actual physical flow of inventory, can lead to higher inventory holding costs, and may not be suitable for items with a long shelf life.

Inventory Forecasting and Planning

Inventory forecasting and planning are crucial in April due to the seasonal fluctuations in demand. Accurate forecasting helps businesses optimize stock levels, minimize carrying costs, and meet customer needs effectively.

Methods for forecasting inventory needs include:

- Historical Data Analysis:Analyzing past sales data to identify trends and patterns in demand.

- Market Research:Conducting surveys, focus groups, or market analysis to gather insights into customer preferences and market dynamics.

- Time Series Analysis:Using statistical techniques to analyze historical data and forecast future demand based on time-related patterns.

To optimize stock levels, businesses can:

- Set Safety Stock Levels:Maintain a buffer stock to absorb unexpected fluctuations in demand.

- Implement Just-in-Time (JIT) Inventory:Minimize inventory levels by receiving goods only when needed.

- Use Inventory Management Software:Automate inventory tracking, forecasting, and reordering to improve efficiency.

Inventory Optimization

Inventory optimization involves techniques for determining the optimal inventory levels to minimize carrying costs while ensuring efficient operations. This optimization balances the trade-off between holding excess inventory, which incurs storage and capital costs, and stockouts, which result in lost sales and customer dissatisfaction.

Inventory optimization tools and technologies, such as inventory management software and demand forecasting algorithms, assist businesses in analyzing historical data, predicting future demand, and setting appropriate inventory levels.

Inventory Optimization Techniques

- ABC Analysis:Classifies inventory items into categories based on their value and demand. High-value, high-demand items (A-items) require more stringent inventory control than low-value, low-demand items (C-items).

- Just-in-Time (JIT) Inventory:Aims to minimize inventory levels by receiving goods only when they are needed for production or sale. JIT requires close coordination with suppliers and accurate demand forecasting.

- Safety Stock:Maintains a buffer inventory to mitigate the risk of stockouts due to unexpected fluctuations in demand or supply chain disruptions.

- Economic Order Quantity (EOQ):Calculates the optimal order quantity to minimize the total cost of inventory, considering factors such as order costs, holding costs, and demand.

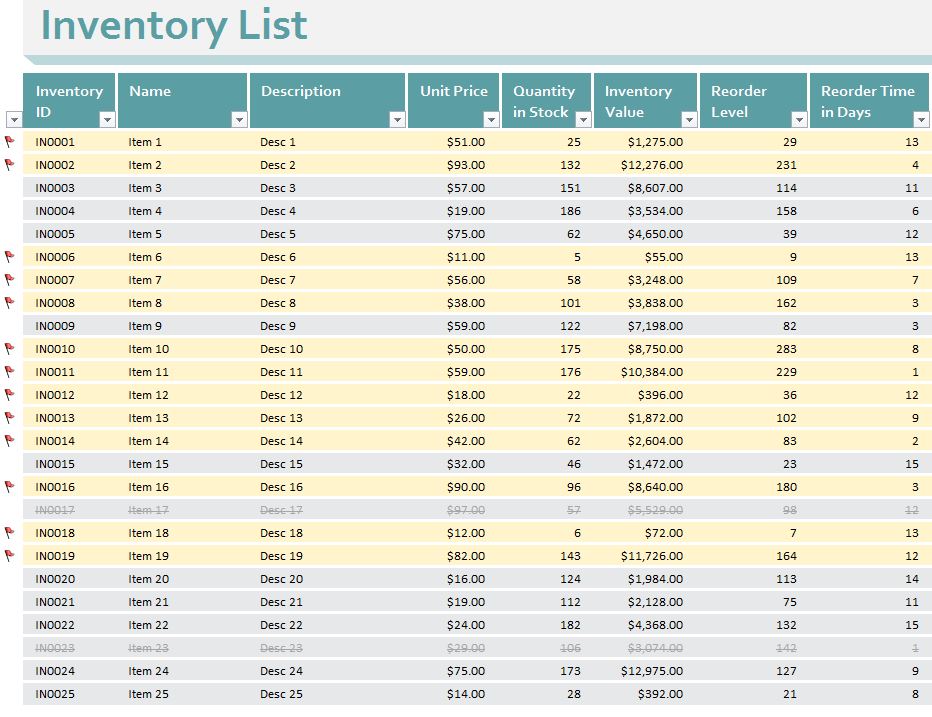

Inventory Reporting and Analysis

Inventory reporting and analysis are crucial in April as businesses prepare for the upcoming fiscal year. It provides insights into inventory levels, turnover rates, and overall inventory management effectiveness.

Inventory reports help businesses identify trends, optimize inventory levels, and make informed decisions about purchasing and production.

Types of Inventory Reports

- Inventory Summary Report:Provides a snapshot of the total inventory value, quantity, and turnover rate.

- Inventory Turnover Report:Measures the number of times inventory is sold and replaced within a specific period.

- Aged Inventory Report:Shows the age of inventory items, highlighting slow-moving or obsolete stock.

- ABC Analysis Report:Classifies inventory items based on their value and turnover rate, helping prioritize inventory management efforts.

- Cycle Counting Report:Tracks discrepancies between physical inventory counts and inventory records, identifying potential errors or theft.

Inventory and Financial Performance

Inventory levels play a crucial role in a company’s financial performance. High inventory levels can tie up cash, increase storage costs, and lead to obsolescence. On the other hand, low inventory levels can result in stockouts, lost sales, and customer dissatisfaction.Effective inventory management can positively impact profitability and cash flow.

By optimizing inventory levels, businesses can reduce holding costs, free up cash for other investments, and improve customer service.

Impact on Profitability

Excess inventory can lead to reduced profitability due to increased storage costs, insurance premiums, and the risk of obsolescence. Moreover, holding excess inventory can tie up capital that could be used for other profitable ventures.

Impact on Cash Flow

High inventory levels can strain a company’s cash flow. When a business purchases inventory, it pays for the goods upfront. However, the cash is not realized until the inventory is sold. This can lead to a cash flow crunch, especially for small businesses with limited access to capital.

Inventory and Supply Chain Management

Inventory plays a crucial role in supply chain management, acting as a buffer between supply and demand. It ensures the availability of goods to meet customer orders while minimizing the risk of stockouts or excess inventory.Integrating inventory management with supply chain operations presents both challenges and opportunities.

One challenge lies in coordinating inventory levels across different stages of the supply chain, including raw materials, work-in-progress, and finished goods. This requires effective communication and collaboration among various departments and stakeholders. Additionally, managing inventory across multiple locations and warehouses can be complex, requiring robust inventory tracking systems and efficient logistics processes.Despite these challenges, integrating inventory management with supply chain operations offers significant opportunities for improving efficiency and profitability.

By optimizing inventory levels, businesses can reduce carrying costs, minimize waste, and enhance customer satisfaction. Moreover, real-time inventory visibility enables better decision-making, allowing businesses to respond quickly to changes in demand or supply disruptions.

Challenges of Integrating Inventory Management with Supply Chain Operations, April business inventories

- Coordinating inventory levels across multiple stages of the supply chain.

- Managing inventory across multiple locations and warehouses.

- Ensuring effective communication and collaboration among various departments and stakeholders.

- Adapting to changes in demand or supply disruptions.

Opportunities of Integrating Inventory Management with Supply Chain Operations

- Reducing carrying costs and minimizing waste.

- Enhancing customer satisfaction by ensuring product availability.

- Improving decision-making through real-time inventory visibility.

- Optimizing inventory levels to maximize profitability.

Industry-Specific Inventory Considerations

Inventory management plays a crucial role in various industries, particularly in April, when businesses prepare for seasonal changes and anticipate increased demand. Some industries where inventory management is particularly critical during this time include:

Retail

* Retailers often experience a surge in demand during April due to the start of the spring season and upcoming holidays like Easter.

Effective inventory management is crucial to ensure that retailers have adequate stock to meet customer demand while avoiding overstocking and potential losses.

Manufacturing

* Manufacturers may need to adjust their inventory levels in April to accommodate changes in production schedules and prepare for upcoming product launches.

Proper inventory management helps manufacturers optimize production efficiency, reduce lead times, and maintain a smooth supply chain.

Automotive

* The automotive industry typically experiences a seasonal increase in demand during April as consumers prepare for warmer weather and outdoor activities.

Dealerships must carefully manage their inventory to ensure they have a sufficient supply of popular models and trims while avoiding excess stock.

Healthcare

* Healthcare providers often face increased demand for medical supplies and equipment in April due to seasonal allergies and the start of flu season.

Effective inventory management is essential for ensuring that healthcare facilities have the necessary supplies to meet patient needs and maintain operational efficiency.

Technology

* The technology industry often experiences new product launches and updates in April, leading to changes in inventory levels.

Retailers and distributors must carefully manage their inventory to ensure they have the latest products in stock while avoiding obsolete or outdated items.

Trends and Innovations in Inventory Management

Inventory management is constantly evolving, with new technologies and best practices emerging all the time. These innovations are helping businesses to improve their inventory accuracy, reduce costs, and increase customer satisfaction.

One of the most significant trends in inventory management is the increasing use of data analytics. Businesses are using data to track inventory levels, identify trends, and make better decisions about how to manage their inventory. This data can be used to improve forecasting, optimize inventory levels, and reduce waste.

Another major trend is the adoption of cloud-based inventory management systems. These systems offer a number of benefits, including improved visibility into inventory levels, real-time updates, and the ability to manage inventory from anywhere. Cloud-based systems are also more scalable than on-premise systems, making them a good option for businesses of all sizes.

In addition to these major trends, there are a number of other innovations that are shaping the future of inventory management. These include:

Artificial Intelligence (AI)

- AI can be used to automate inventory tasks, such as forecasting demand and optimizing inventory levels.

- AI can also be used to identify patterns and trends in inventory data, which can help businesses to make better decisions.

Radio Frequency Identification (RFID)

- RFID tags can be attached to inventory items to track their location and movement.

- This data can be used to improve inventory accuracy, reduce theft, and optimize inventory levels.

Blockchain

- Blockchain is a distributed ledger technology that can be used to track inventory transactions.

- This data can be used to improve transparency and accountability in the supply chain.

3D Printing

- 3D printing can be used to create custom inventory items on demand.

- This can help businesses to reduce inventory costs and improve customer service.

These are just a few of the trends and innovations that are shaping the future of inventory management. As these technologies continue to develop, businesses will be able to improve their inventory accuracy, reduce costs, and increase customer satisfaction.

Concluding Remarks: April Business Inventories

In conclusion, April business inventories present a multifaceted landscape that requires careful planning, strategic decision-making, and continuous improvement. By embracing the principles Artikeld in this guide, businesses can transform their inventory management practices, enhance operational efficiency, and unlock the full potential of their inventory investments.

Top FAQs

What are the key inventory management strategies commonly used in April?

Businesses often adopt strategies such as just-in-time inventory, safety stock management, and vendor-managed inventory to optimize their inventory levels during April.

How can businesses forecast inventory needs effectively in April?

Time series analysis, historical data analysis, and demand forecasting techniques are valuable tools for predicting inventory requirements and ensuring optimal stock levels.

What are the benefits of optimizing inventory levels in April?

Inventory optimization helps businesses reduce carrying costs, minimize waste, improve customer service, and enhance overall operational efficiency.