As the digital landscape evolves, automate inventory control small business is emerging as a crucial strategy for small businesses to thrive in the competitive market. By leveraging technology to automate inventory management processes, businesses can unlock a world of benefits, including improved accuracy, reduced costs, and enhanced customer satisfaction.

This comprehensive guide delves into the world of inventory control automation, empowering small businesses with the knowledge and tools to make informed decisions and streamline their operations.

In this guide, we will explore the types of inventory control automation systems available, their features and capabilities, and the benefits they offer. We will also discuss the challenges of implementing automation and provide solutions to overcome them. Additionally, we will share case studies and success stories of small businesses that have successfully implemented inventory control automation, demonstrating the transformative impact it can have on business operations.

Overview of Inventory Control Automation for Small Businesses

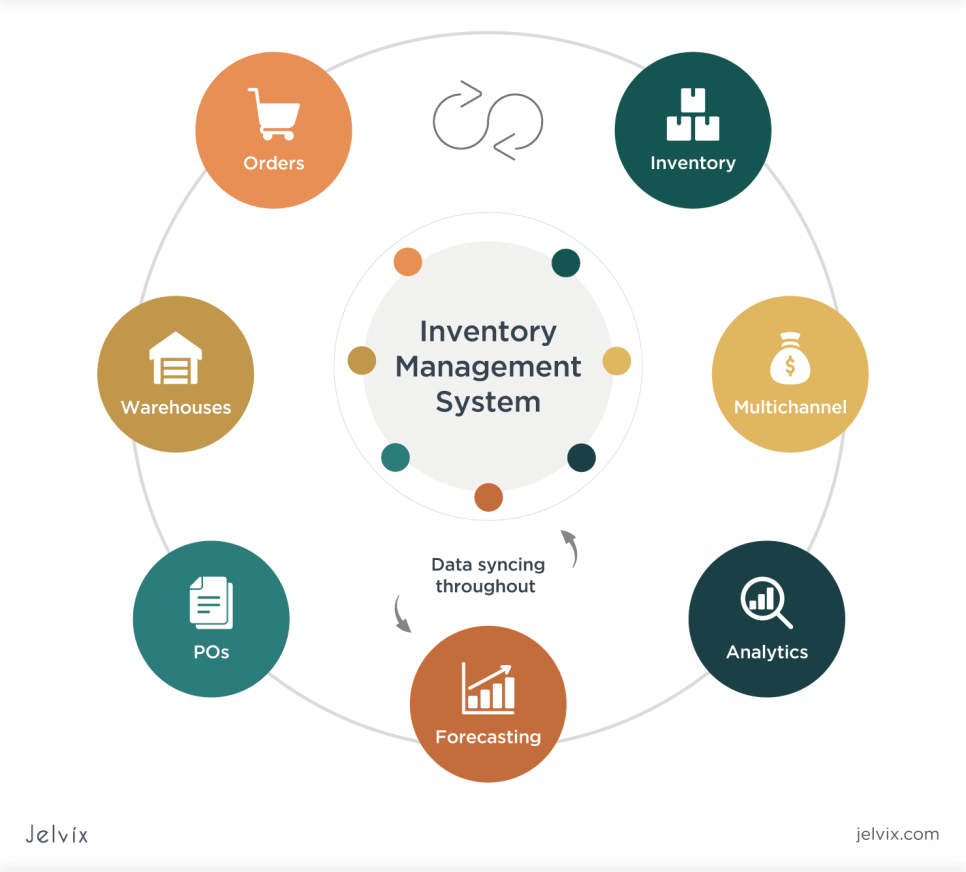

Inventory control automation streamlines inventory management processes for small businesses, reducing manual tasks, improving accuracy, and providing real-time visibility into inventory levels.

Through automated processes like real-time tracking, inventory forecasting, and automated reordering, small businesses can optimize inventory levels, reduce waste, and improve customer satisfaction.

Benefits of Inventory Control Automation

- Reduced manual labor and human error

- Improved accuracy in inventory tracking

- Real-time visibility into inventory levels

- Optimized inventory levels, reducing waste and overstocking

- Improved customer satisfaction through reduced stockouts

How Automation Streamlines Inventory Management

Inventory control automation software integrates with existing systems, automating tasks such as:

- Tracking inventory levels in real-time

- Forecasting demand and generating automated purchase orders

- Managing inventory transfers and adjustments

- Providing alerts for low stock levels and expiring items

- Generating inventory reports and analytics

Types of Inventory Control Automation Systems

Inventory control automation systems streamline inventory management processes, providing real-time visibility and control over stock levels. These systems offer a range of features and capabilities, catering to the specific needs of small businesses.

Inventory control automation systems can be categorized into two main types:

Cloud-Based Solutions

Cloud-based inventory control systems are hosted on remote servers, accessible via the internet. They offer several advantages, including:

- Accessibility:Accessible from any device with an internet connection, enabling remote inventory management.

- Scalability:Easily scalable to accommodate business growth without the need for additional hardware or infrastructure.

- Lower Costs:Typically more cost-effective than on-premise solutions, as businesses only pay for the services they use.

- Automatic Updates:Systems are automatically updated with the latest features and security patches, ensuring ongoing functionality.

On-Premise Solutions

On-premise inventory control systems are installed on a local server or computer within the business’s premises. They offer greater control over data security and customization, but also require significant upfront investment and ongoing maintenance.

- Control:Businesses have complete control over their data and system configuration.

- Customization:Systems can be tailored to meet specific business requirements and workflows.

- Security:Data is stored locally, reducing the risk of unauthorized access or data breaches.

- Higher Costs:Require upfront investment in hardware, software, and maintenance, which can be significant for small businesses.

The choice between cloud-based and on-premise solutions depends on factors such as budget, IT resources, data security concerns, and the level of customization required.

Benefits of Inventory Control Automation: Automate Inventory Control Small Business

Inventory control automation offers numerous advantages for small businesses, resulting in significant return on investment (ROI). Let’s explore the benefits in detail:

Improved Accuracy

- Automated systems eliminate manual errors, leading to more accurate inventory counts.

- Real-time tracking reduces discrepancies between physical inventory and records.

- Improved accuracy enables businesses to optimize stock levels, minimize overstocking, and prevent stockouts.

Reduced Costs

- Automation reduces labor costs associated with manual inventory management.

- Accurate inventory levels help prevent overstocking, which reduces storage costs.

- Optimized stock levels minimize waste and spoilage, leading to cost savings.

Enhanced Customer Satisfaction

- Accurate inventory data ensures that customers receive their orders promptly.

- Reduced stockouts improve customer loyalty and reduce order cancellations.

- Real-time inventory tracking enables businesses to respond quickly to customer inquiries.

Time-Saving Advantages and Increased Efficiency, Automate inventory control small business

- Automation eliminates the need for manual inventory counting, freeing up time for other tasks.

- Automated systems streamline inventory management processes, reducing overall time spent.

- Increased efficiency allows businesses to focus on other aspects of their operations.

Challenges of Implementing Inventory Control Automation

Implementing inventory control automation systems can bring numerous benefits, but it also poses several challenges for businesses.One common challenge is the lack of technical expertise within the organization. Inventory control automation systems require specialized knowledge and skills to configure, operate, and maintain.

Businesses may need to invest in training or hire external consultants to bridge this knowledge gap.Another challenge is the potential disruption to existing business processes. Implementing an automation system often requires changes to the way inventory is managed and tracked.

This can lead to temporary disruptions and inefficiencies until the new system is fully integrated and staff are adequately trained.Finally, the cost of implementing an inventory control automation system can be a significant barrier for small businesses. The cost of hardware, software, and ongoing maintenance can add up quickly, and businesses need to carefully evaluate the potential return on investment before making a decision.

Overcoming Challenges

To overcome these challenges, businesses should consider the following best practices:

Assess needs and goals

Clearly define the specific inventory management challenges that the automation system aims to address. This will help in selecting the right system and ensuring that it meets the business’s specific needs.

Involve stakeholders

Get buy-in from key stakeholders, including inventory managers, warehouse staff, and accounting personnel. This will help ensure that the system is designed to meet their needs and that they are invested in its success.

Provide training and support

Invest in comprehensive training for all users of the automation system. This will help them understand how to use the system effectively and minimize disruptions during implementation. Ongoing support should also be provided to address any issues that may arise.By carefully planning for and addressing these challenges, businesses can increase the likelihood of successful implementation and maximize the benefits of inventory control automation.

Choosing the Right Inventory Control Automation System

Selecting the right inventory control automation system is crucial for small businesses to optimize their operations. Consider the following factors when making your decision:

- Business size:Smaller businesses may need a simpler system, while larger businesses require a more robust solution.

- Industry:Different industries have unique inventory management requirements. Choose a system tailored to your specific industry.

- Specific needs:Identify your specific inventory management challenges and select a system that addresses them effectively.

To evaluate different systems, create a decision matrix that compares their features, functionality, and cost. Consider the following aspects:

Features and Functionality

- Inventory tracking capabilities

- Order management and fulfillment

- Reporting and analytics

- Integration with other business systems

Cost

- Initial investment

- Ongoing subscription or maintenance fees

- Implementation and training costs

Vendor Support

- Availability and responsiveness of support

- Training and documentation provided

By carefully considering these factors, small businesses can choose the right inventory control automation system to streamline their operations and improve efficiency.

Case Studies and Success Stories

Inventory control automation has proven to be a game-changer for small businesses, streamlining operations and boosting profitability. Let’s explore case studies that showcase the transformative impact of automation:

Case Study: ABC Electronics

ABC Electronics, a small electronics retailer, struggled with inventory inaccuracies and overstocking. After implementing an inventory control automation system, they experienced:

- Reduced inventory costs by 15%:Optimized stock levels minimized overstocking and obsolete inventory.

- Improved customer satisfaction by 20%:Accurate inventory data ensured products were always available, reducing backorders.

- Increased sales by 10%:Automated inventory tracking freed up time for sales staff to focus on customer engagement.

Testimonial from the Owner:“Inventory control automation was the best investment we’ve made. It’s not just about saving money; it’s about improving our customer experience and growing our business.”

Case Study: XYZ Manufacturing

XYZ Manufacturing, a small-scale manufacturer, faced challenges with managing inventory across multiple warehouses. By automating their inventory control system, they achieved:

- Reduced labor costs by 25%:Automated inventory tracking eliminated the need for manual counting and data entry.

- Improved inventory accuracy by 95%:Real-time inventory visibility ensured accurate tracking and reduced errors.

- Optimized production planning:Automated inventory data provided insights into inventory levels and demand patterns, enabling better production planning.

Testimonial from the Operations Manager:“Inventory control automation has been a lifesaver for our business. It has given us complete control over our inventory, reduced costs, and improved our overall efficiency.”

End of Discussion

Embracing automate inventory control small business is a strategic move that can propel small businesses towards growth and success. By implementing the right automation system, businesses can streamline their operations, reduce costs, and enhance customer satisfaction. As technology continues to advance, inventory control automation will become increasingly essential for small businesses to remain competitive and thrive in the ever-changing market landscape.

Top FAQs

What are the benefits of automating inventory control?

Automating inventory control offers numerous benefits, including improved accuracy, reduced costs, enhanced customer satisfaction, time savings, and increased efficiency.

What types of inventory control automation systems are available?

There are various types of inventory control automation systems available, including cloud-based systems, on-premise systems, and hybrid systems. Each type has its own set of features and capabilities, and the best choice for a particular business will depend on its specific needs and requirements.

What are the challenges of implementing inventory control automation?

Some common challenges of implementing inventory control automation include resistance to change, lack of technical expertise, data accuracy issues, and integration with existing systems. However, with proper planning, training, and support, these challenges can be overcome.