Welcome to the world of business inventory articles, where we delve into the fascinating realm of inventory management. From best practices to optimization strategies, valuation methods, and control systems, these articles provide a comprehensive guide to managing inventory effectively and efficiently.

Inventory plays a crucial role in any business, affecting everything from customer satisfaction to financial performance. By understanding the intricacies of inventory management, businesses can optimize their operations, reduce costs, and gain a competitive edge.

Inventory Management Techniques: Business Inventory Articles

Inventory management is crucial for businesses to maintain optimal stock levels, reduce waste, and ensure efficient operations. Effective inventory management practices can lead to improved customer satisfaction, increased profitability, and reduced costs.

Best Practices for Inventory Management

Some best practices for inventory management include:

- Establish clear inventory policies and procedures:This ensures consistency and accountability in inventory management practices.

- Conduct regular inventory audits:This helps identify discrepancies between physical inventory and records, preventing overstocking or stockouts.

- Implement a perpetual inventory system:This provides real-time visibility into inventory levels, allowing businesses to make informed decisions about stock replenishment.

- Use inventory forecasting techniques:This helps businesses predict future demand and optimize inventory levels accordingly.

- Optimize inventory storage and handling:This includes implementing proper storage techniques, FIFO (first-in, first-out) inventory management, and minimizing inventory damage.

Examples of Successful Inventory Management Strategies

Successful inventory management strategies vary depending on the industry and business size. Some common strategies include:

- Just-in-time (JIT) inventory:This strategy involves maintaining minimal inventory levels and relying on frequent deliveries to meet demand.

- Vendor-managed inventory (VMI):In this strategy, the supplier manages the inventory levels for the business.

- Safety stock:This involves holding additional inventory to buffer against unexpected fluctuations in demand or supply.

Benefits of Implementing Inventory Management Systems

Implementing inventory management systems can provide numerous benefits, including:

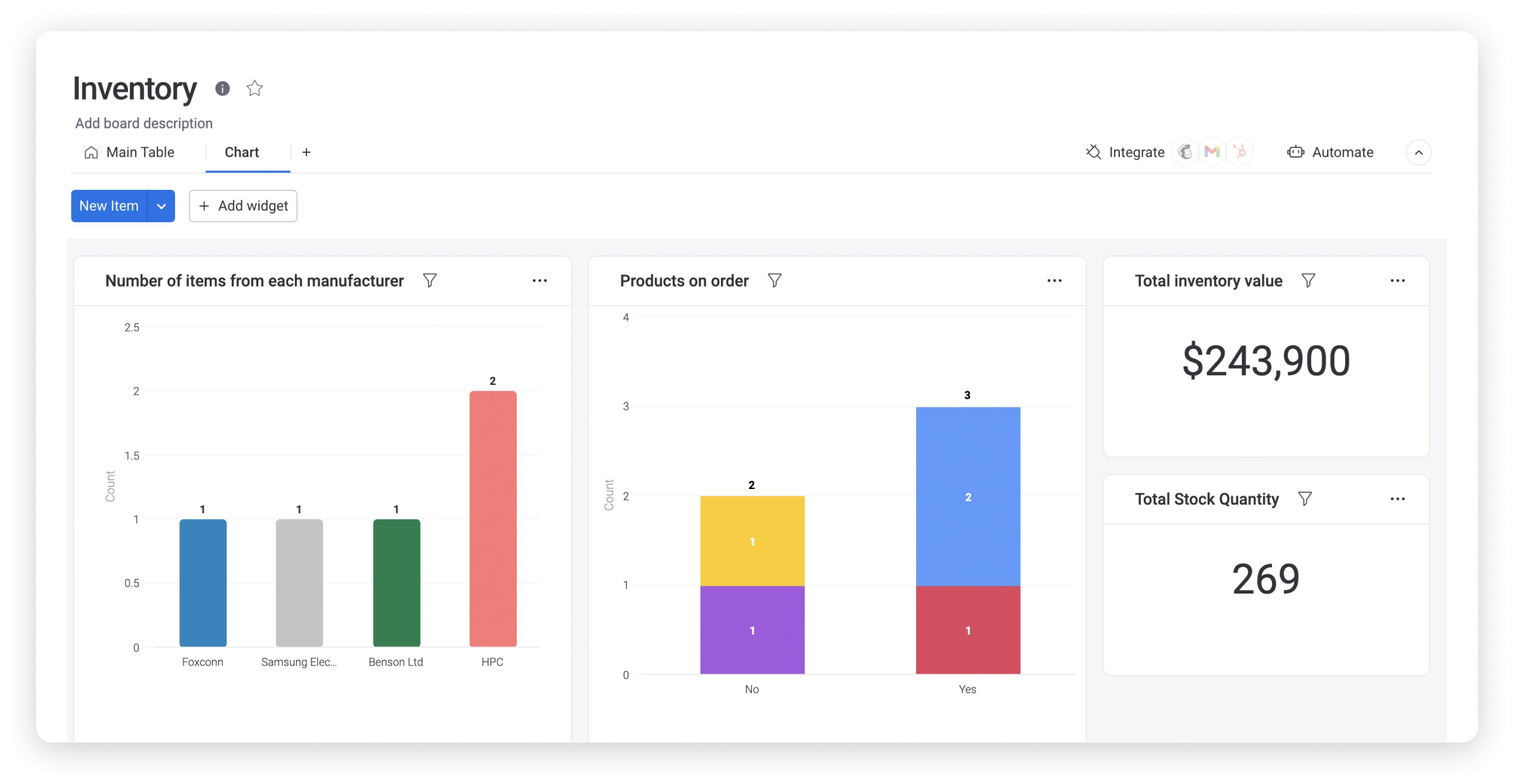

- Improved inventory accuracy:Systems automate inventory tracking and reduce errors, leading to more accurate inventory records.

- Enhanced visibility and control:Systems provide real-time visibility into inventory levels, allowing businesses to make informed decisions about stock replenishment and avoid overstocking or stockouts.

- Reduced costs:Systems help optimize inventory levels, reducing holding costs, waste, and spoilage.

- Improved customer satisfaction:Accurate inventory management ensures that businesses can meet customer demand and avoid backorders.

Inventory Optimization Strategies

Inventory optimization involves employing strategies to minimize inventory levels while ensuring adequate stock to meet customer demand. It aims to reduce waste, improve efficiency, and enhance overall inventory management.

Effective inventory optimization relies on accurate demand forecasting, data analysis, and continuous improvement.

Forecasting Demand

Accurate demand forecasting is crucial for optimizing inventory levels. Techniques such as historical data analysis, trend analysis, and machine learning algorithms can be employed to predict future demand patterns.

- Historical data analysis examines past sales data to identify trends and seasonality.

- Trend analysis involves identifying long-term patterns in demand, considering factors like economic conditions and market trends.

- Machine learning algorithms leverage historical data to create predictive models that forecast future demand based on various input variables.

Adjusting Inventory Levels

Based on demand forecasts, inventory levels should be adjusted to maintain optimal stock levels. This involves balancing the need to meet customer demand with the costs of holding excess inventory.

- Safety stock is maintained to buffer against unexpected fluctuations in demand.

- Minimum stock levels ensure that there is always a sufficient quantity of inventory on hand.

- Maximum stock levels set an upper limit on inventory levels to prevent overstocking.

Data Analysis

Data analysis plays a vital role in inventory optimization. By analyzing inventory data, businesses can identify patterns, trends, and areas for improvement.

- Inventory turnover ratio measures the efficiency of inventory management.

- Days of inventory on hand indicates the average number of days it takes to sell through inventory.

- ABC analysis categorizes inventory items based on their value and demand, allowing for targeted inventory management strategies.

Inventory Valuation Methods

Inventory valuation methods are techniques used to assign a monetary value to the inventory held by a company. Accurate inventory valuation is crucial for financial reporting, tax purposes, and decision-making. There are several different inventory valuation methods, each with its own advantages and disadvantages.

Specific Identification Method

The specific identification method assigns a unique cost to each unit of inventory. This method is most accurate but also the most time-consuming and expensive to implement. It is typically used for high-value or unique items, such as jewelry or antiques.

First-In, First-Out (FIFO) Method

The FIFO method assumes that the oldest inventory is sold first. This method is relatively easy to implement and is often used for perishable goods or items with a high turnover rate. However, FIFO can result in overstated inventory values during periods of inflation.

Last-In, First-Out (LIFO) Method

The LIFO method assumes that the most recently purchased inventory is sold first. This method can result in understated inventory values during periods of inflation but can provide tax benefits. LIFO is often used for companies with large inventories of commodities.

Weighted Average Cost Method

The weighted average cost method assigns an average cost to all units of inventory. This method is relatively easy to implement and can provide a more stable inventory value than FIFO or LIFO. However, it can result in overstated or understated inventory values depending on the timing of purchases and sales.

Impact of Inventory Valuation on Financial Statements

The choice of inventory valuation method can have a significant impact on a company’s financial statements. For example, FIFO can result in higher reported profits during periods of inflation, while LIFO can result in lower reported profits. This can affect a company’s tax liability, stock price, and other financial ratios.

Inventory Control Systems

Inventory control systems are designed to track and manage the flow of inventory within a business. An effective system can help businesses reduce costs, improve customer service, and increase profitability.

The components of an effective inventory control system include:

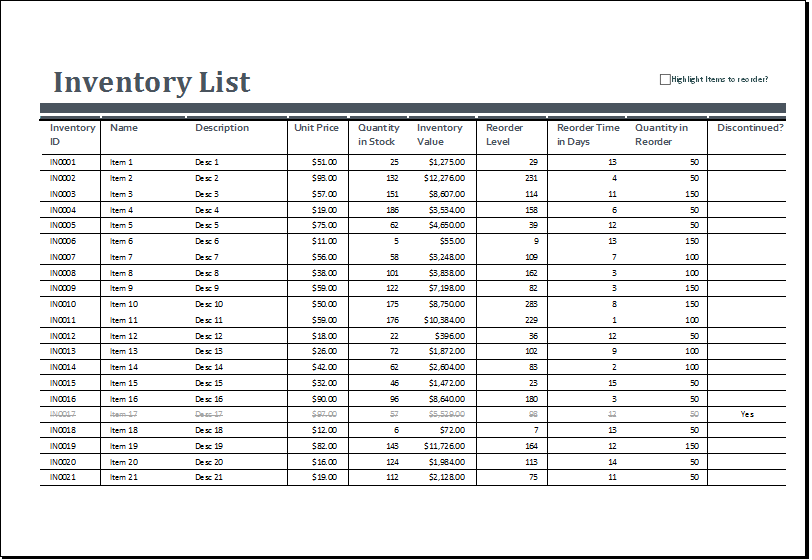

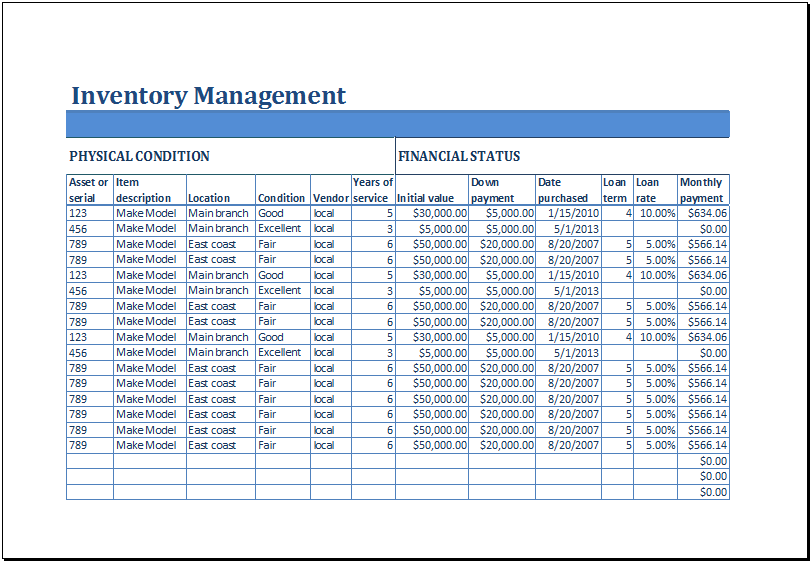

- Inventory records:These records keep track of the quantity, location, and status of all inventory items.

- Inventory tracking:This process involves tracking the movement of inventory items from the time they are received until they are shipped to customers.

- Inventory valuation:This process involves determining the value of inventory items for financial reporting purposes.

- Inventory control policies:These policies establish the rules and procedures for managing inventory.

Technology plays a vital role in inventory control. Inventory management software can help businesses automate many of the tasks associated with inventory control, such as tracking inventory levels, generating reports, and placing orders.

Some examples of inventory control best practices include:

- Using a perpetual inventory system:This system provides real-time information on inventory levels.

- Setting safety stock levels:This ensures that businesses have enough inventory on hand to meet demand.

- Conducting regular inventory audits:This helps to ensure that inventory records are accurate.

Inventory Management in Different Industries

Inventory management practices vary across industries due to unique challenges and operational requirements. Understanding these industry-specific nuances is crucial for optimizing inventory levels, minimizing costs, and enhancing customer satisfaction.

Retail Industry, Business inventory articles

- High product variety:Retailers deal with a wide range of products, requiring complex inventory management systems to track stock levels and ensure availability.

- Seasonal fluctuations:Demand for products varies significantly throughout the year, necessitating inventory adjustments to meet seasonal peaks and avoid overstocking.

- Rapid turnover:Fast-moving consumer goods (FMCG) have a short shelf life, demanding efficient inventory management to prevent spoilage and stockouts.

Manufacturing Industry

- Complex supply chains:Manufacturers rely on multiple suppliers for raw materials and components, making inventory management critical for ensuring smooth production flow.

- Work-in-progress (WIP) inventory:Managing WIP inventory is essential to avoid production bottlenecks and ensure timely delivery of finished goods.

- Just-in-time (JIT) inventory:JIT inventory management aims to minimize inventory levels and reduce carrying costs, but requires close coordination with suppliers and efficient production processes.

Healthcare Industry

- Critical inventory:Healthcare facilities must maintain adequate stock levels of essential medical supplies and pharmaceuticals to ensure patient safety.

- Expiration dates:Pharmaceuticals and medical devices have expiration dates, requiring careful inventory management to prevent waste and ensure patient well-being.

- Regulatory compliance:Healthcare inventory management must comply with industry regulations to ensure patient safety and data privacy.

Technology Industry

- Rapid product innovation:Technology products have short lifecycles, making inventory management challenging due to the need to manage obsolete and end-of-life products.

- High-value inventory:Technology products are often expensive, requiring secure inventory storage and efficient tracking systems to prevent theft and loss.

- E-commerce fulfillment:Online retailers in the technology industry require robust inventory management systems to handle high order volumes and ensure timely delivery.

Conclusion

In conclusion, business inventory articles offer invaluable insights and practical guidance for businesses looking to master inventory management. By implementing the strategies and techniques discussed in these articles, organizations can streamline their operations, improve efficiency, and achieve greater profitability.

Essential FAQs

What are the key inventory management techniques?

Effective inventory management techniques include ABC analysis, just-in-time inventory, and safety stock management.

How can businesses optimize inventory levels?

Inventory optimization strategies involve forecasting demand, setting appropriate inventory levels, and using data analysis to monitor and adjust inventory as needed.

What are the different inventory valuation methods?

Common inventory valuation methods include FIFO (first-in, first-out), LIFO (last-in, first-out), and weighted average cost.