Business inventory buyers, the unsung heroes of the business world, play a pivotal role in ensuring that companies have the right products, in the right quantities, at the right time. Their expertise in inventory management strategies, sourcing, and technology empowers businesses to optimize their operations and maximize profitability.

From understanding the different types of inventory buyers and their functions to exploring the latest tools and techniques for inventory optimization, this comprehensive guide delves into the fascinating world of business inventory buyers.

Business Inventory Buyers

Business inventory buyers, also known as purchasing agents or procurement managers, are responsible for acquiring the necessary inventory to support the day-to-day operations of a business. They play a critical role in ensuring that the business has the right quantity of inventory on hand to meet customer demand while minimizing costs and maximizing profitability.

There are different types of business inventory buyers, each with their own specific responsibilities. Some of the most common types of inventory buyers include:

Types of Business Inventory Buyers

- Raw material buyerspurchase raw materials that are used to manufacture finished goods.

- Component buyerspurchase components that are used to assemble finished goods.

- Finished goods buyerspurchase finished goods that are sold to customers.

- MRO buyerspurchase maintenance, repair, and operating supplies that are used to keep a business running.

Inventory Management Strategies for Business Inventory Buyers

Inventory management strategies are crucial for business inventory buyers to optimize stock levels, minimize costs, and enhance customer satisfaction. Effective inventory management involves balancing inventory levels to meet demand while avoiding overstocking or stockouts.

Inventory Optimization

Inventory optimization is the process of determining the ideal inventory levels to meet demand without incurring excessive holding costs. Techniques for inventory optimization include:

- Economic Order Quantity (EOQ):Calculates the optimal order quantity to minimize total inventory costs, considering ordering costs and holding costs.

- Just-in-Time (JIT):Aims to minimize inventory levels by receiving goods only when needed, reducing storage and holding costs.

- Safety Stock:Maintains a buffer inventory to protect against unexpected demand fluctuations or supply chain disruptions.

Inventory Forecasting

Inventory forecasting involves predicting future demand to determine appropriate inventory levels. Methods for inventory forecasting include:

- Time Series Analysis:Analyzes historical demand patterns to predict future demand.

- Regression Analysis:Uses statistical models to predict demand based on independent variables such as price or seasonality.

- Causal Analysis:Identifies and analyzes factors that influence demand, such as marketing campaigns or economic conditions.

Sourcing and Supplier Relationships

Inventory sourcing and supplier relationship management are critical aspects of inventory management for business inventory buyers. Establishing a reliable and efficient supply chain ensures the availability of inventory to meet customer demand and optimize business operations.

The process of sourcing inventory involves identifying, evaluating, and selecting suppliers who can provide the required products or materials at competitive prices and meet the quality standards of the business. Inventory buyers must conduct thorough research, assess supplier capabilities, and negotiate favorable terms to ensure a reliable supply chain.

Supplier Evaluation

Evaluating suppliers involves assessing their financial stability, production capacity, quality control measures, and customer service capabilities. Business inventory buyers should consider factors such as supplier reputation, references from previous customers, and industry certifications to ensure they are partnering with reliable and trustworthy suppliers.

Negotiating Favorable Terms, Business inventory buyers

Negotiating favorable terms with suppliers is crucial to optimize costs and ensure a mutually beneficial relationship. Inventory buyers should consider factors such as pricing, payment terms, delivery schedules, and minimum order quantities. By understanding the supplier’s cost structure and market dynamics, buyers can negotiate terms that align with the business’s financial objectives and operational needs.

Supplier Relationship Management

Establishing and maintaining strong supplier relationships is essential for long-term success. Inventory buyers should foster open communication, build trust, and work collaboratively with suppliers to resolve issues and improve performance. Regular supplier meetings, performance reviews, and joint problem-solving can strengthen relationships and ensure a reliable supply chain.

Technology and Tools for Business Inventory Buyers

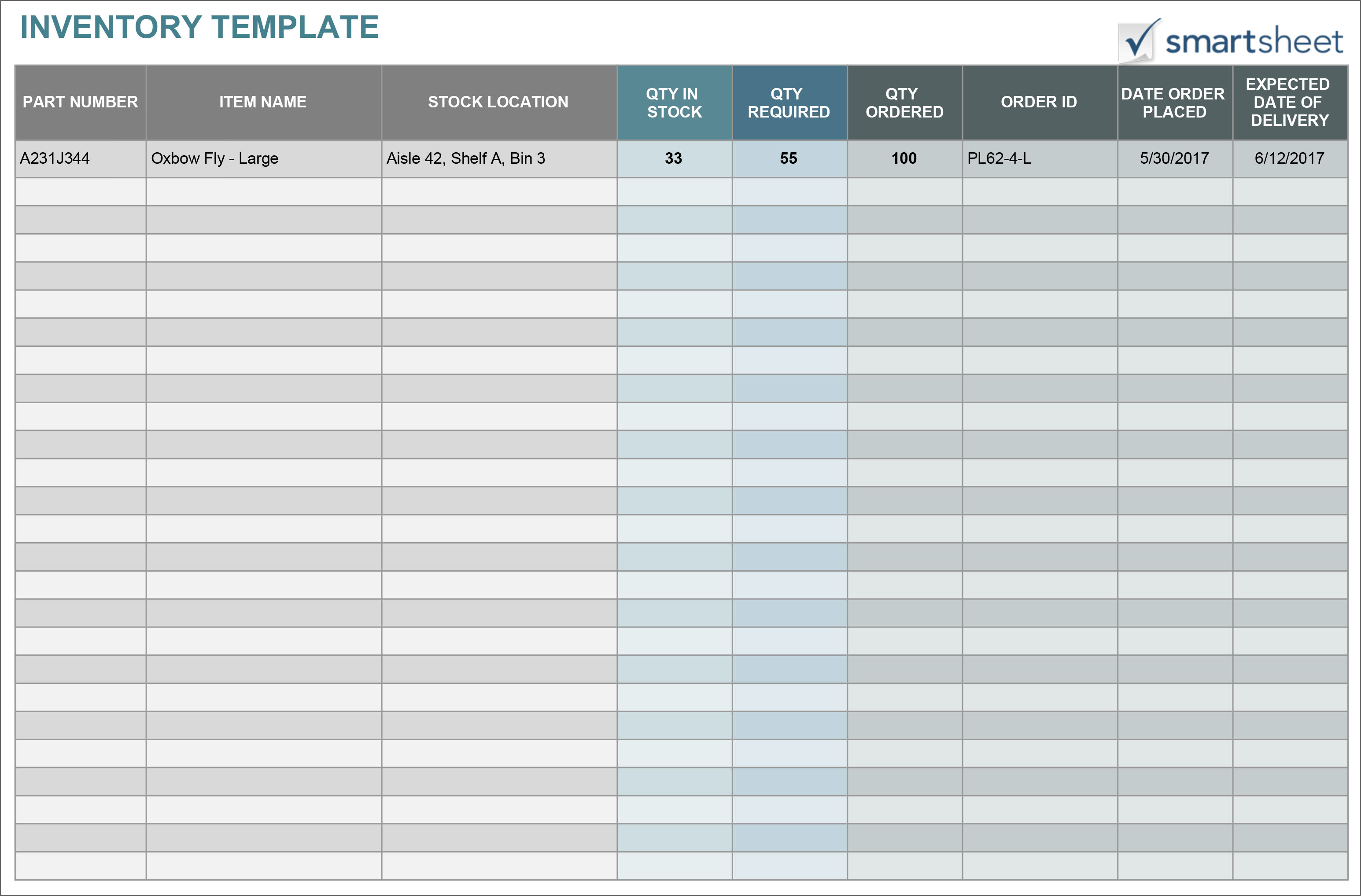

Technology plays a crucial role in empowering business inventory buyers to optimize their inventory management practices. Inventory management software offers a comprehensive suite of features that streamline operations, improve efficiency, and enhance decision-making.

Inventory Management Software

- Real-time visibility:Provides real-time insights into inventory levels, location, and movement, enabling buyers to make informed decisions.

- Demand forecasting:Analyzes historical data and market trends to predict future demand, helping buyers optimize stock levels.

- Automated reordering:Sets up automated reordering rules based on inventory levels, lead times, and safety stock levels.

- Supplier management:Manages supplier relationships, tracks performance, and facilitates collaboration.

- Warehouse optimization:Optimizes warehouse operations by providing insights into space utilization, picking efficiency, and inventory turnover.

Data Analytics and Reporting Tools

Data analytics and reporting tools empower business inventory buyers to extract valuable insights from their inventory data. These tools enable buyers to:

- Identify trends and patterns:Analyze inventory data to identify trends, patterns, and areas for improvement.

- Generate reports:Create customizable reports that provide insights into inventory performance, supplier performance, and stock levels.

- Make informed decisions:Use data-driven insights to make informed decisions about inventory levels, supplier selection, and warehouse operations.

Ethical Considerations and Sustainability

Ethical considerations and sustainability play a vital role in modern inventory management practices for business inventory buyers. Businesses have a responsibility to conduct their operations in a manner that aligns with ethical principles and minimizes their environmental impact.

Responsible Sourcing Practices

- Ethical Sourcing:Business inventory buyers must ensure that their suppliers adhere to ethical labor practices, fair wages, and safe working conditions.

- Conflict-Free Sourcing:Buyers should avoid sourcing materials from conflict zones or areas where human rights violations occur.

- Transparency and Traceability:Maintaining transparency in the supply chain allows buyers to trace the origin of materials and ensure compliance with ethical and sustainability standards.

Reducing Waste and Environmental Impact

Business inventory buyers can significantly reduce waste and minimize their environmental impact through various practices:

- Inventory Optimization:Effective inventory management techniques help businesses maintain optimal stock levels, reducing the risk of excess inventory and waste.

- Waste Reduction Initiatives:Buyers can implement programs to reduce waste, such as recycling, composting, and exploring alternative packaging solutions.

- Energy Efficiency:Utilizing energy-efficient equipment and practices in warehouses and distribution centers can minimize the carbon footprint.

Closing Summary: Business Inventory Buyers

In conclusion, business inventory buyers are indispensable partners in the success of any organization. Their ability to manage inventory efficiently, build strong supplier relationships, and leverage technology sets them apart as true masters of their craft. As businesses navigate the ever-changing landscape of commerce, the role of inventory buyers will continue to evolve, ensuring that companies remain competitive and agile in the face of new challenges.

FAQ Corner

What is the primary responsibility of a business inventory buyer?

To ensure that a company has the right products, in the right quantities, at the right time, while minimizing costs and waste.

What are some common inventory management strategies used by business inventory buyers?

Just-in-time inventory, safety stock management, vendor-managed inventory, and drop shipping.

How do business inventory buyers source products?

Through a variety of channels, including online marketplaces, trade shows, and direct negotiation with suppliers.